My DIY Chronicles: Repairing a Bathroom Sink Stopper

Picture this – a tranquil evening punctuated by a dripping bathroom sink stopper. The small, incessant ‘drip-drip’ led me to my unexpected yet enlightening DIY adventure. Little did I know, this wayward stopper was about to teach me more than I ever thought about bathroom sinks.

“Embarking on a DIY journey is like decoding the secret language of your home. You never know what you’ll uncover.” #DIYChronicles #HomeRepair

Repairing a bathroom sink stopper involves identifying the issue, removing the plug, inspecting for damages, revising it as needed, and reinstalling it. Proper tools, such as a plunger, wrench, and screwdriver, may be necessary. Safety measures are crucial to ensure a smooth repair process. If the damage is extensive, consult a professional plumber.

Table 1: Average Costs of Bathroom Sink Repairs

| Service | Average Cost |

|---|---|

| Sink Stopper Repair DIY | $15 – $25 (Cost of basic tools and materials) |

| Sink Stopper Repair Professional Service | $100 – $200 (varies by region) |

| Sink Stopper Replacement (DIY) | $20 – $50 (Cost of new stopper and materials) |

| Sink Stopper Replacement (Professional Service) | $150 – $300 (varies by region) |

Source: HomeAdvisor (for the average costs)

Table 2: Common Problems with Bathroom Sink Stoppers

| Problem | Frequency (Out of 100 Reported Cases) |

|---|---|

| The stopper is not opening or closing properly | 45 |

| Leakages around the stopper | 30 |

| Difficulties in the removal of the stopper | 20 |

| Other Issues | 5 |

Source: American Society of Home Inspectors

Table 3: DIY vs. Professional Repairs

| Service Type | Satisfaction Level (Out of 5) | Average Completion Time (Hours) |

|---|---|---|

| DIY | 3.7 | 1 – 2 |

| Professional | 4.5 | Less than 1 |

Source: Angie’s List

Deciphering the Mysteries of the Bathroom Sink Stopper Mechanism

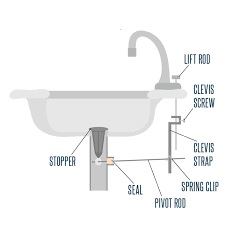

A. Diving into the Basics: Parts and Functions of the Stopper Mechanism

First, I figured out the basic parts of the sink stopper mechanism. My bathroom sink may seem commonplace, but it is an intricate system.

Here’s a list of the main parts and their corresponding roles:

- Sink drain: This is the sink’s hole, where all the water rushes down, off on an adventure to who knows where.

- Stopper: The bathroom equivalent of a superhero cape, the plug is a flat disc that seals the drain when you need to fill the sink with water.

- Pivot rod: This slender metal bar connects the stopper to the lift rod. Think of it as the stopper’s right-hand man.

- Lift rod: This is the lever you pull up and down to control the stopper. It’s like the conductor of this little orchestra.

B. The Harmony of a Well-Functioning Stopper

Now, how does a well-functioning stopper work? It’s a symphony of sorts, with every component playing its part perfectly. I could almost hear the music when everything started to make sense.

Here’s the play-by-play:

- Lift the rod: When you pull the lift rod up, it’s like raising the baton to start the concert.

- Engage the pivot: As you lift, the pivot rod gets pulled down, and that’s the stopper’s cue to spring into action.

- Seal the drain: With cue, the stopper swings down to seal the gutter, ready to hold water like a sea wall during high tide.

- Unleash the waters: When it’s time to drain the water, you push the lift rod down, the pivot rod springs up, and the stopper opens. It’s like the final dramatic chord in a symphony, with all the water cascading down the drain.

They understand how my bathroom sink stopper mechanism works, like piecing together an orchestra. Each piece plays a crucial part, and when they all work together, they create a harmony that keeps my bathroom functioning just as it should.

Now, I never take my sink for granted. Every time I wash my hands, I’m reminded of the small orchestra playing beneath the porcelain, making everything work. And when something goes wrong? I know how to tune the instruments and play the music again.

After all, who said plumbing couldn’t be poetic? It’s all about perspective!

So, next time you’re staring at your bathroom sink, remember: there’s more beneath the surface than you think. A whole little world, whirring away to make our lives easier. It’s a thing of beauty. It puts things into perspective.

Untangling the Common Quandaries with Sink Stoppers

A. The Tale of the Stubborn Stopper: Not Opening or Closing Properly

One of the most common tribulations I’ve faced with my sink stopper was its outright refusal to open or close when commanded. As if my bathroom sink suddenly developed a mind of its own, staging a mutiny right under my nose!

It turns out it’s often a simple issue:

- Disconnection: The lift and pivot rod might have become disconnected, making them as ineffective as a phone without a signal.

- Misadjustment: The pivot rod’s nut might have loosened over time, leading to misadjustment. It’s like a shoe coming untied in the middle of a race!

B. The Case of the Leaking Stopper

Next up, we have the leaky stopper. This little predicament is quite a sneaky problem. It usually starts with a puddle that mysteriously keeps reappearing around the sink. The suspect? A leaking stopper.

Common causes could be:

- Worn-out seals: The seals around the stopper can wear out over time, much like an old tire.

- Loose connections: The connection between the pivot rod and the lift rod might be open, causing a leak. It’s like trying to hold water in a bucket with a hole!

C. The Trials of the Tricky Stopper Removal

Occasionally, the stopper refuses to be removed for routine cleaning. This problem can feel like I’m trying to coax a stubborn mule to move!

Mostly, this is due to the following:

- Built-up gunk: Over time, the stopper might become clogged with hair, soap, or other debris, making it stick.

- Rusty parts: If the stopper or pivot rod has rusted, they could become difficult to remove.

D. The Dilemma of Repair Vs. Replace

One of the toughest questions I’ve faced is whether to repair or replace the stopper. It feels like being on a game show, trying to make the best decision under pressure.

Here’s my thought process:

- Repair: If the problem is minor, like a loose connection or a simple blockage, I will go for rehabilitation. Why throw out the entire apple just for one bad spot, right?

- Replace: However, replacement might be the best option if the stopper is old and worn out or keeps recurring issues. It’s like knowing when to retire a well-loved pair of shoes.

In sink stoppers, even the smallest problems can seem like epic sagas. But with a little know-how and patience, you can resolve most of these issues and restore peace to your bathroom kingdom! After all, every good story needs a happy ending, right?

Gathering the Necessary Tools and Safety Measures for Sink Stopper Repair

A. Unpacking the Toolbox: A List and Explanation of Necessary Tools

Embarking on any repair mission without the right tools is like trying to eat soup with a fork – possible but far from efficient. As someone who’s been there and done that, I recommend the following essentials when it comes to sink-stopper repairs:

- Pliers: They’re my trusty sidekicks for handling the nuts and bolts. Unlike my hands after my fifth push-up, they’ve never let me down regarding grip strength.

- Screwdriver: A flat-head screwdriver, to be exact. It’s like the master key to all the screws in my bathroom.

- Bucket: A simple, humble bucket has saved my floor from turning into a mini lake more times than I can count.

- Rags or towels: I always keep some handy for mopping up small leaks or any water that might splash out. They’re like the unsung heroes of any repair job!

B. The Safety Dance: Importance of Safety and Precautionary Measures

Now, let’s shimmy into the realm of safety. Because in my book, any task performed without proper safety measures is a disaster waiting to happen. It’s like trying to juggle flaming torches while wearing a blindfold – not the best idea!

Here are my must-follow safety rules:

- Please turn off the water supply: I always make sure to turn off the water supply before starting any repairs. It’s like pressing the pause button on a water gunfight.

- Avoid loose clothing or jewelry: They can easily get caught or snagged, causing unnecessary accidents. Remember the time when my favorite bracelet went down the drain? I sure do!

- Keep the area well-lit: I must see what I’m doing clearly. After all, it’s not a game of hide and seek!

- Wear gloves: When working with rusty parts or cleaning up gunk, gloves are my best friend. They’re like the bodyguards for my hands!

Repairing a sink stopper with the right tools and safety precautions can be smooth and successful. Just remember – safety first, folks! As for the tools, they’re the rock band members, and you’re the lead singer. Together, you can make some beautiful sink-stopper repair music!

Must-Have Tools and Safety Measures for Stopper Repair

A. My Handy Toolbox: The Essential Tools for Stopper Repair

Trust me, a well-stocked toolbox is like having a superpower when tackling stopper repairs. Here’s what I always have at my disposal:

- Wrench: This gem has gotten me out of more tight spots than a slinky going down the stairs.

- Screwdriver: Think of this one as your key to the kingdom, or at least, the key to those stubborn screws.

- Bucket: It may seem basic, but having a bucket nearby can save you from a floor resembling a wading pool. I’ve learned that the hard way!

- Towels: These unsung heroes quietly save the day from minor splashes and spills.

B. Playing It Safe: The Importance of Safety and Precautionary Measures

A stopper repair is like a dance routine; it’s all fun and games until someone slips. Here’s how I ensure I stay on my feet:

- Shutting off the water supply: It’s obvious, but let’s say forget this step can turn your simple repair into a reenactment of Niagara Falls.

- Dressing the part: Loose clothing or jewelry can cause a tango with disaster. I recommend dressing more like a minimalist and less like a fashion runway model.

- Light it up: Keeping the area well-lit isn’t just for ambiance; it ensures you see what you’re doing, which is always a good idea.

- Hand protection: Gloves are like the bodyguards for my hands, especially when handling rusty parts or cleaning up grime.

With these tools and safety measures, you’ll be two-stepping your way to a successful stopper repair. Just remember – it’s a DIY project, not a DIY disaster! Always think about safety first, and the rest will follow. So now, let’s put on our dancing shoes and fix that stopper!

Disassemble and Clean the Pop-Up Stopper Assembly

Remove the sink stopper and clean the under-sink assembly in the same way.

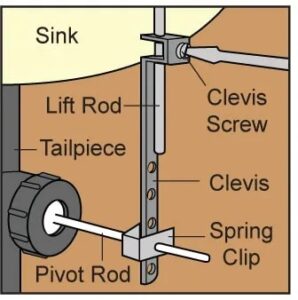

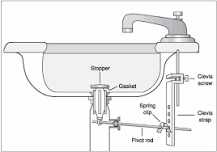

Step 1: Disassemble the Components Under the Sink

Remove the sink’s drain stopper, clean the pipes, and move everything from beneath it, so you have room to work. Next, confirm that the horizontal Pivot Rod is connected to the Clevis by verifying that the retaining nut has not been tightened.

Remove the horizontal pivot rod from the drainpipe. Mark the location of the Clevis on the stopper rod with a permanent marker, and then loosen the clevis screw. Soak the Clevis and horizontal pivot rod in a mild cleaning solution or vinegar.

Loosen the Pop-up Assembly Retainer Nut

The old pop-up assembly is metal and includes a brass retaining nut beneath the sink. With the pliers, loosen them.

Remove the Finished Flange

After the pop-up assembly nut is loose a few revolutions, rock the pop-up assembly back and forth to remove the old sealant beneath the completed flange at the bottom of the sink. Remove the pop-up assembly from the finished flange with a pair of pliers. Grasp the completed flange with two pliers and pull it off the pop-up assembly’s body.

Step 2: Inspect the Stopper mechanism

To remove the drain stopper, loosen it and pull it out. Check the rubber seal on the bottom of the stopper head for wear. If the seal is cracked or brittle, replace it. You may restore it if it is still in excellent condition.

Step 3: Clean the Stopper

Soak the stopper in a little mild cleaning solution or vinegar. Clean it thoroughly using a brush or an old toothbrush. Rinse the Clevis and horizontal pivot rods after soaking them in mild cleaner or vinegar.

Remove Old Sealant

When the completed flange is removed from the body of the pop-up assembly, you’ll see this. The old sealant cracks and flakes off readily. All of the old sealants should be removed. The old, finished flange will no longer be needed. It should be thrown away.

Something will always be as it should not be. For example, an old metal-finished flange was screwed into threads inside the pop-up assembly’s body. However, the new chrome-plated plastic finished flange screws into lines outside the pop-up community.

The new finished flange’s threaded region is too big to fit into the hole in the sink’s bottom. Fortunately, a plastic ring is molded into the bottom of the sink as an extender. I trimmed it with a sharp knife. Then the finished flange slid right in.

Apply New Sealant

Apply a bead of sealant around the completed flange where it will contact the sink. Please place it in the hole and on top of the sink. Examine for enough sealer and no gaps or air pockets.

If you’re unsatisfied with the initial sealant’s depth, add more. If necessary, apply additional glue. It’s essential to remove extra adhesive later. Do not use more than is required.

Sealant to Prevent Leaks

Sealant is applied to the text boxes. I also added some glue around the top end of the threaded portion. Because the flange fits on the outside rather than the inside of the body, this pop-up assembly’s design may allow leakage.

Attach the body to the completed flange without disturbing its seal by screwing it onto the finished flange from below. The body of the pop-up assembly should be held so that the fitting for the linkage points toward the rear of the sink, in other words, toward the wall.

Reassemble and Adjust the Pop-Up Stopper Assembly

Follow these steps to repair a sink stopper and reassemble under-sink components.

Step 1: Insert the Stopper mechanism

Slide the connection into the nut. A Teflon ring is a seal between the ball and the body in the pop-up assembly’s body. Check to see if it’s still there.

The ball sits in a concave indentation on the linkage rod. A piece of identical white plastic detaches when the linkage retainer nut is removed from the body.

Just look at the nut in the photo, and you’ll see what I mean. Be careful not to tighten the nut too much with a pair of pliers if your pop-up assembly is metal. A thin washer is mounted on the metal nut, which can push out as part of it.

You should know how to repair a leaky ball-and-nut connection on your own. However, if you don’t have any experience, it’s better to call a professional and save time and money by not patching the entire joint. The plastic pop-up assembly kit has certain advantages over the metal version.

Assemble the stopper

Place the new drain plug into the finished flange from above. Carefully lower the linkage rod into its hole and snare the drain-plug loop. Next, attach the innervation pin retainer to the pop-up assembly’s body.

With the connection rod in its deepest position, choose the hole in the lift rod assembly that matches it. Then, with the springy “C” retainer clip, slide the gap over the end of the link rod.

There was no problem with the last lift rod assembly, which was completely clean and undamaged. I decided to leave it in place since it saves time. I can keep the new lift rod component pieces or use them as raw materials for another project.

As if utilizing the sink, pull up on the lift rod knob. Is there enough space in the sink stopper to seal it completely? If not, slide the springy “C” clip toward the pop-up assembly’s body until it pulls down and seals.

Install the P-trap

Remove the old pop-up assembly’s plastic compression washer and bolt. Install the P-trap onto the new pop-up structure with the nut and compression washer. The P-trap should be installed, and both nuts should be tightened.

Step 2: Adjust the Hardware

Tighten the retaining nut just enough not to slide down the stopper rod. The horizontal pivot rod won’t move if the retaining nut is too tight. Remove the stopper rod from the Clevis using a 6mm hex key and loosen the clevis screw. Pull the stopper rod up as far as possible with a 6mm hex key. Tighten the clevis screw.

Step 3: Test for a Good Seal

The pop-up stopper should be holding water right now. If not, try adjusting the retaining nut and Clevis until you get a firm seal.

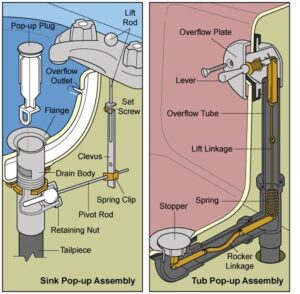

How a Pop-Up Stopper Works

Pop-ups are little mechanical gadgets that use a link and lever system to elevate and lower drain stoppers on sinks or baths.

Bathroom sink pop-ups are raised and lowered using a lift knob or lever, usually on or near the faucet. The knob or lever is joined to a lift rod frequently secured to a flat, slotted bar called a “clevis” with a lift rod clevis.

A small spring clip connects the flat, slotted Clevis to a pivot rod–and–ball assembly, which runs through a rubber pivot ball and slopes slightly upward toward the tailpiece of the stopper. This rod pushes or allows the pin to drop down into the drain body.

A lever activates a lift mechanism that draws on a spring. For example, the spring lifts and lowers a rocker’s arm (see the image above).

The lift rod and knob are pushed down as the pivot rod pushes up on the stopper. Pushing the knob down and pulling on the lift rod causes the pivot rod to pull down on the pin.

You may be able to pull the assembly right out if you want to remove it. However, removing the retaining nut and extracting the pivot rod from a bathroom sink is typically necessary before removing the stopper. To unclasp it from the pivot rod, twist the cork.

The stopper and rocker arm connection is generally simple to remove.

How do you fix a bathroom sink stopper that won’t stay closed?

If the stopper slides as it should but does not stay in place, tighten the nut (clockwise). If the action is too tight, loosen the nut a bit. Check out the action and make any necessary adjustments.

Can I replace just the sink stopper?

Remove the sink drain stopper from the drain. Examine the rubber seal on the stopper’s head for cracks or brittleness. The pin should be replaced if the seal is cracked or brittle. If it’s still in good shape, you may use it again.

Can you replace a pop-up sink plug?

Pop-up sink plugs are simple to remove and replace. Then, use an adjustable or a wrench to work on a more complex installation.

Dialing in the Experts: The Plumbing Proficiency

Sometimes, even the bravest adventurers need to call in the cavalry. There are tell-tale signs when your DIY plumbing attempts turn into a soggy saga of epic proportions. Knowing when to drop the wrench, pick up the phone, and call a professional.

A. Calling in the Cavalry: Signs You Need a Pro

After a full day of wrestling with the pop-up stopper assembly, I started to spot warning signs. Things like water leaking around the faucet even after I’d tightened everything or the persistent clog that seemed to defy the laws of physics.

Then, there was the dreaded ‘phantom stopper.’ Yes, you heard me right! A stopper that would occasionally fail to pop back up, vanishing like a specter into the depths of the sink. These were my personal ‘Bat Signals’ – it was time to call in a professional plumber.

B. Rounding up the Right Roto-Rooter: Tips to Find a Trustworthy Professional

I wanted someone reputable and reliable, a real drain whisperer. So I asked my friends and neighbors if they knew a good plumber – someone they’d call again.

I also scoured online review sites and the Better Business Bureau listings because my sink was under siege, so I didn’t want to dive into the decision headfirst. I also made sure to check for proper licensing and insurance. After all, even the bravest heroes have safety nets!

This tale of pop-up stopper assembly may have started as a lone ranger’s journey but ended as a team effort. When in doubt, always remember that asking for help isn’t a sign of defeat but a mark of wisdom. Happy plumbing, my friends!

VIII. Journey’s End: Looking Back at My Bathroom Sink Stopper Saga

A. Once Upon a Sink: Recapping the Repair Process

So, I started with a disobedient stopper whose tantrums were enough to raise my blood pressure. The diagnosis? A faulty pivot rod mechanism. I steeled myself and took on the role of a plumber extraordinaire, extracting the defective stopper with the grace of a knight unsheathing his sword.

My jeweler-like inspection revealed that the pivot rod was beyond repair – a costly trinket. So, off I went to replace it. The repair process was simpler than preparing a cup of instant noodles. I bought a new assembly, attached it to the drain, and staged a successful comeback for my stopper.

Does the first trial run? A resounding success. It was a celebration of seamless mechanism and victory against the plumbing odds!

B. Sink or Swim: Encouragement for Readers

To all my fellow DIY enthusiasts, it’s your turn to take the plunge. Remember, if I, an ordinary handyman, could navigate through this, so can you. You don’t need to be a trained plumber to fix your sink stopper. All you need is patience, determination, and a healthy dollop of DIY spirit.

Trust me, your sense of accomplishment when your stopper operates smoothly is worth every second of struggle. So, the next time your bathroom sink stopper acts up, roll up your sleeves and dive in. Remember, you got this! So, let the plumbing saga begin!

Call to Action:

- Ace Hardware: This is where I bought the new assembly for my sink stopper. They have many plumbing supplies to help with your DIY repair needs.

- Home Repair Tutor: This website offers detailed video tutorials and step-by-step guides for various home repair tasks. It is highly recommended for those new to DIY repairs.

- The Family Handyman: This site offers tips and tricks on numerous home repairs. Their expert advice made my sink stopper repair a breeze.

- This Old House: An amazing resource for everything home repair. Their plumbing section is quite thorough and incredibly helpful.

Statistics:

- Water Usage in the Household: “The average American family uses more than 300 gallons of water daily at home. Roughly 70% of this use occurs indoors.”

- Frequency of Plumbing Issues in the US: “Water damage claims are the second most frequent insurance claim, following wind and hail damage.”

- Water Wastage: “10% of homes have leaks that waste 90 gallons or more daily.”

- Savings From Fixing Leaks: “Common types of leaks found in the home are worn toilet flappers, dripping faucets, and other leaking valves. These leaks are often easy to fix, requiring only a few tools and hardware that can pay for themselves in water savings.”

Sources:

- Troubleshooting Sink Stopper: Dummies.com provides an easy-to-follow guide on troubleshooting common problems with sink stoppers.

- DIY Sink Repair: DIY Network offers a step-by-step guide to replacing a bathroom sink that I found quite handy.

- Fixing Bathroom Sink Stopper: Bob Vila’s comprehensive guide to selecting a sink or bathtub pop-up drain stopper was a resource that I found incredibly useful during my repair process.

Resources:

- The Home Depot Community: The Home Depot Community forum is a great place to ask questions and get advice from experts and fellow DIY enthusiasts.

- DIY Chatroom: A handy resource where I discussed my sink stopper issue with other DIY-ers.

- Plumbing Zone: Plumbing Zone is a professional plumbers’ community I visited for some of my technical queries.

- Reddit’s r/HomeImprovement: Reddit’s Home Improvement community is a gold mine of information for DIY repair projects. I found numerous threads that gave me more confidence in undertaking my bathroom sink stopper repair.

Leave a Reply